“Decon Consulting Engineers” was established in the year 1994 to initiate business in consultancy, Design, Engineering, Manufacturing & Fabrication of various equipment & system in different industrial discipline. In its moves towards the Millennium, ‘Decon’ has diversified its fields of business to various service application viz. ‘Metal Stitching’ & ‘Online Leak Sealing’.

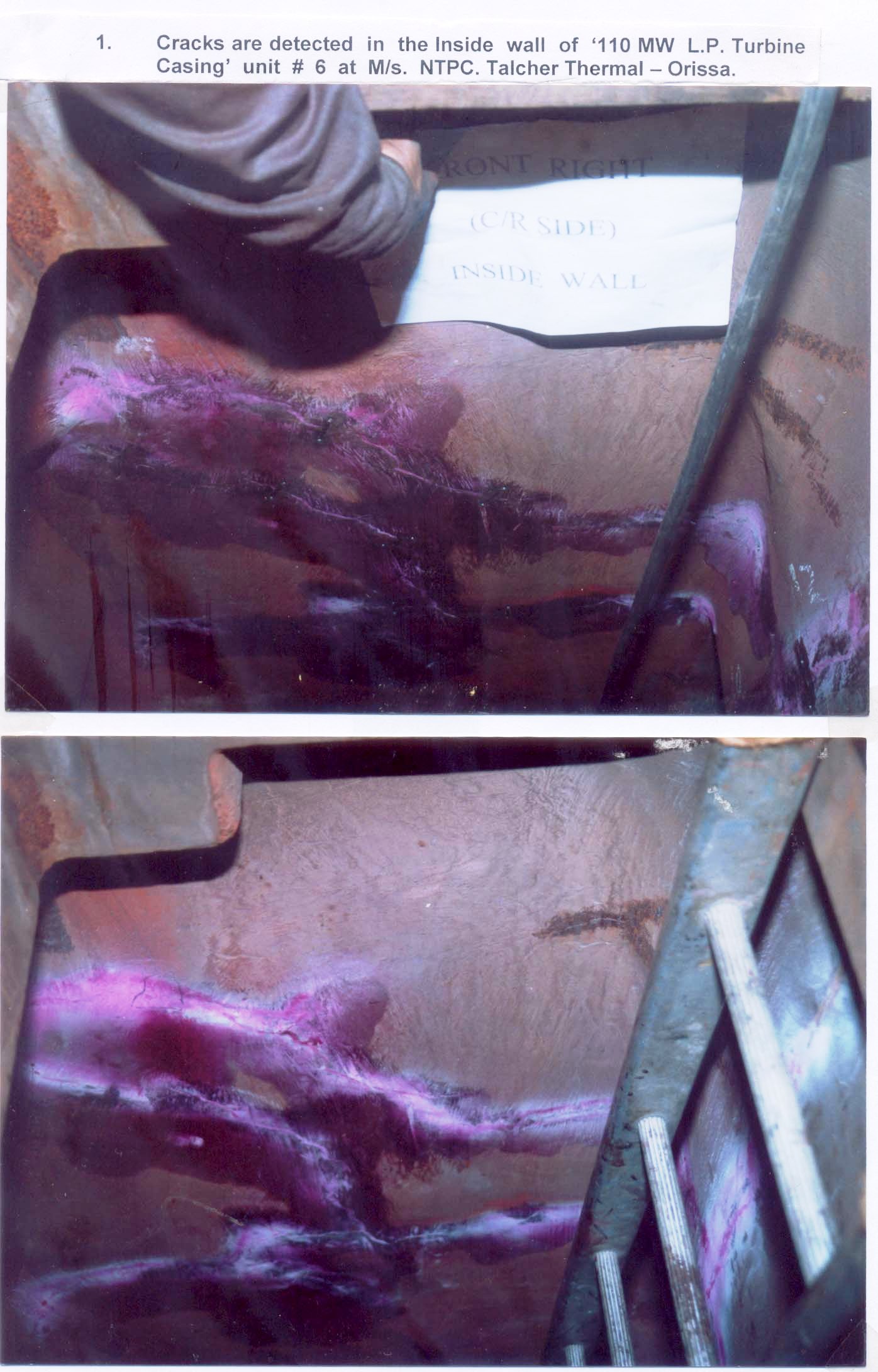

ABOUT METAL STITCHING

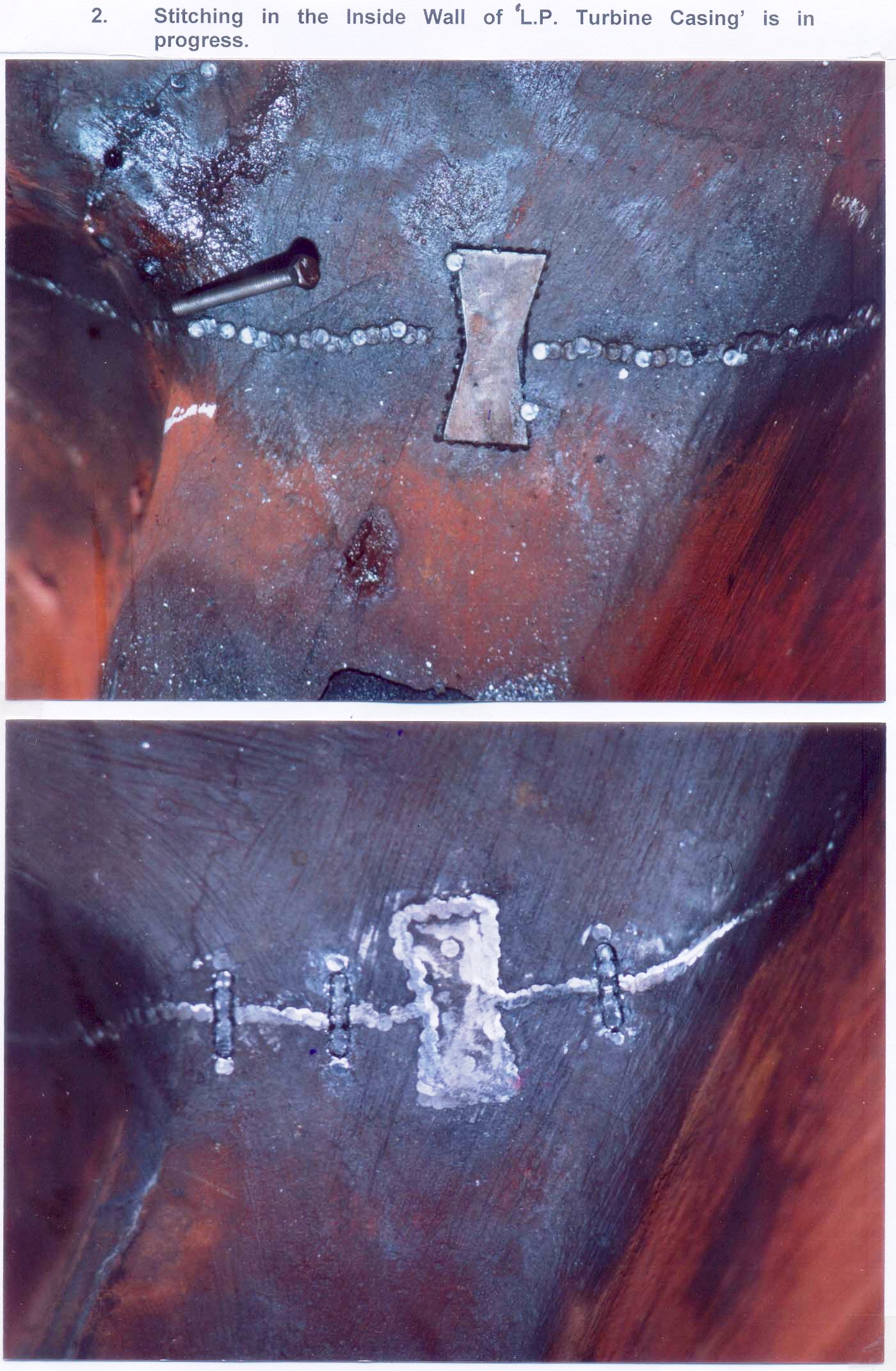

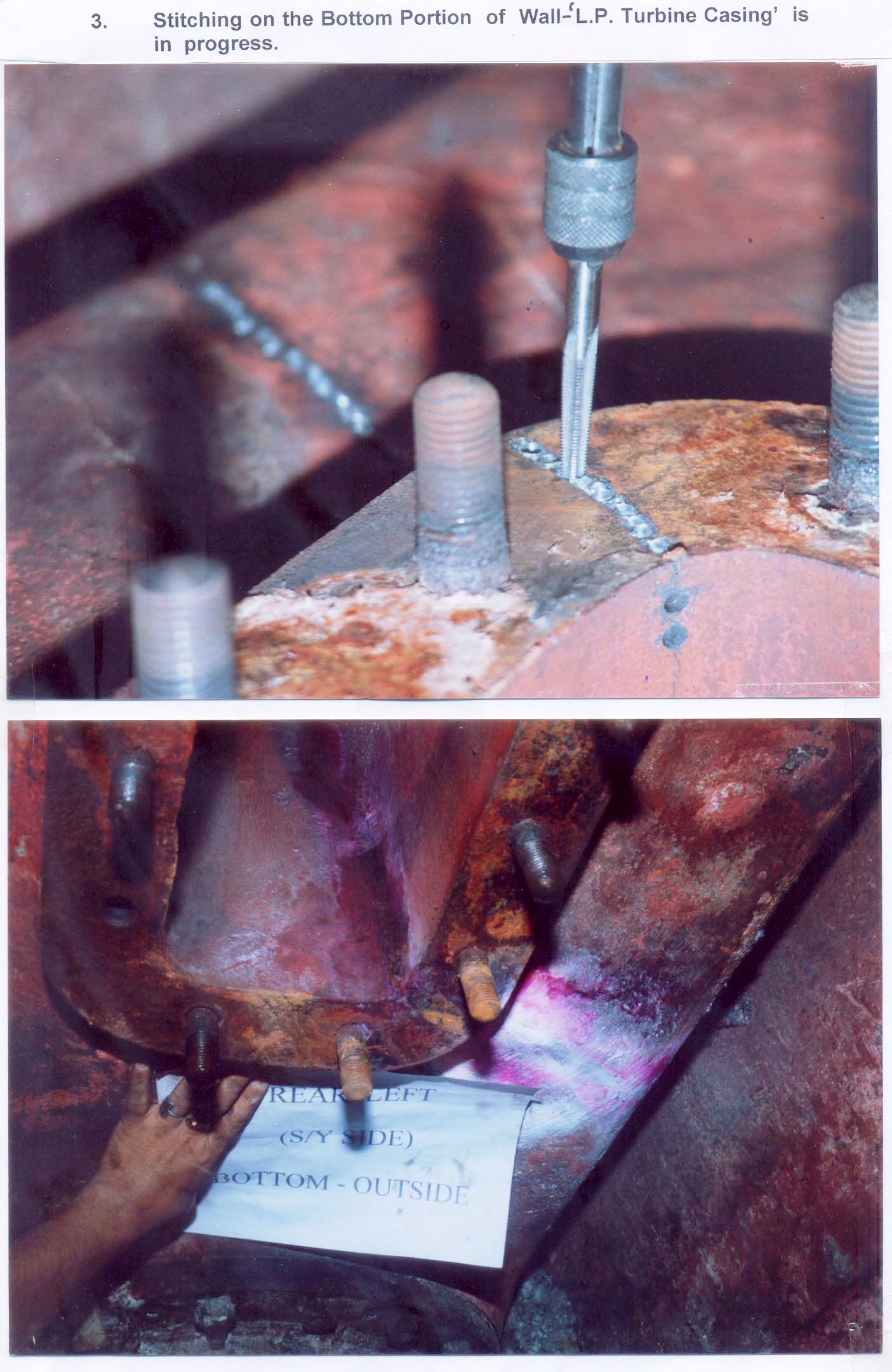

WHAT IS A METAL STITCHING?

This is a cold repairing process for repair of cracked, broken & blown off casting. This is an unique process for repair of Cast Iron, Cast Steel & Cast Aluminum machineries & equipment. It holds strongly even where welding fails.

|

Repairing of broken Alternator Body

in a Marine Engine on-Shore |

|

Patch plate stitched on blown-off portion

of Marine Engine by using Dovetail |

WHAT ARE THE ADVANTAGES?

-

| |

The job is undertaken at site & situ condition. |

-

| |

Dismantling is not required normally. |

-

| |

The repair being completely cold does not require any application of heat thereby avoiding thermal stress & grain structure of the parent material remain unchanged even after repair. |

-

| |

Inherent stress in the casting are relieved. |

-

| |

The process permits 100 percent Leak Free repair of crack in pressure parts. |

-

| |

The process of repairing will save the time & cost of re-casting. |

APPLICATION:

Repair of cracked, Broken & Blown off parts of Engine Block, Cylinder Head, Turbo charger, Crank case, Gear Box Housing, Pump Casing & pedestal, Mining Equipment, Generator, Lathe, Presses, Milling Machine, Turbine Casing, Induction Motor Broken Legs, Forging Hammer Body & any type of Casted Parts, Machineries or Equipment.

|

| Cylinder Head of MW Engine, crack in combustion chamber repaired by Metal Stitching |

PROCESS:

1) Visible & Invisible cracks are identified.

2) Holes are drilled across the length of crack at suitable intervals for the Master locks, their shape & size vary depending upon the strength requirement of the job.

3) Taper threaded plugs are placed along the length of crack overlapping each other to ensure a leak proof repair.

4) Hand grinders are used to give a clean & smooth finish to the repaired portion.

Plug stitching on

Plug stitching on

crack portion

Stitching Process is going

Stitching Process is going

in overlapped manner

LIMITATIONS:

Ni-Hard casting/Alloy Cast Iron or any other metal whose hardness exceeds more than 350 BHN cannot be repaired by metal stitching process due to the hardness induced by Heat Treatment. Metal stitching process is limited upto maximum temperature of 750°C.

SERVICE:

Our service is available 24 hours a day, 7 days a week through out the year. Prior to undertake a repair work, a pre-execution inspection is necessary. Detailed information from client in the equipment, length & depth of the crack, approximate hardness etc., would enable Decon to respond properly.

|

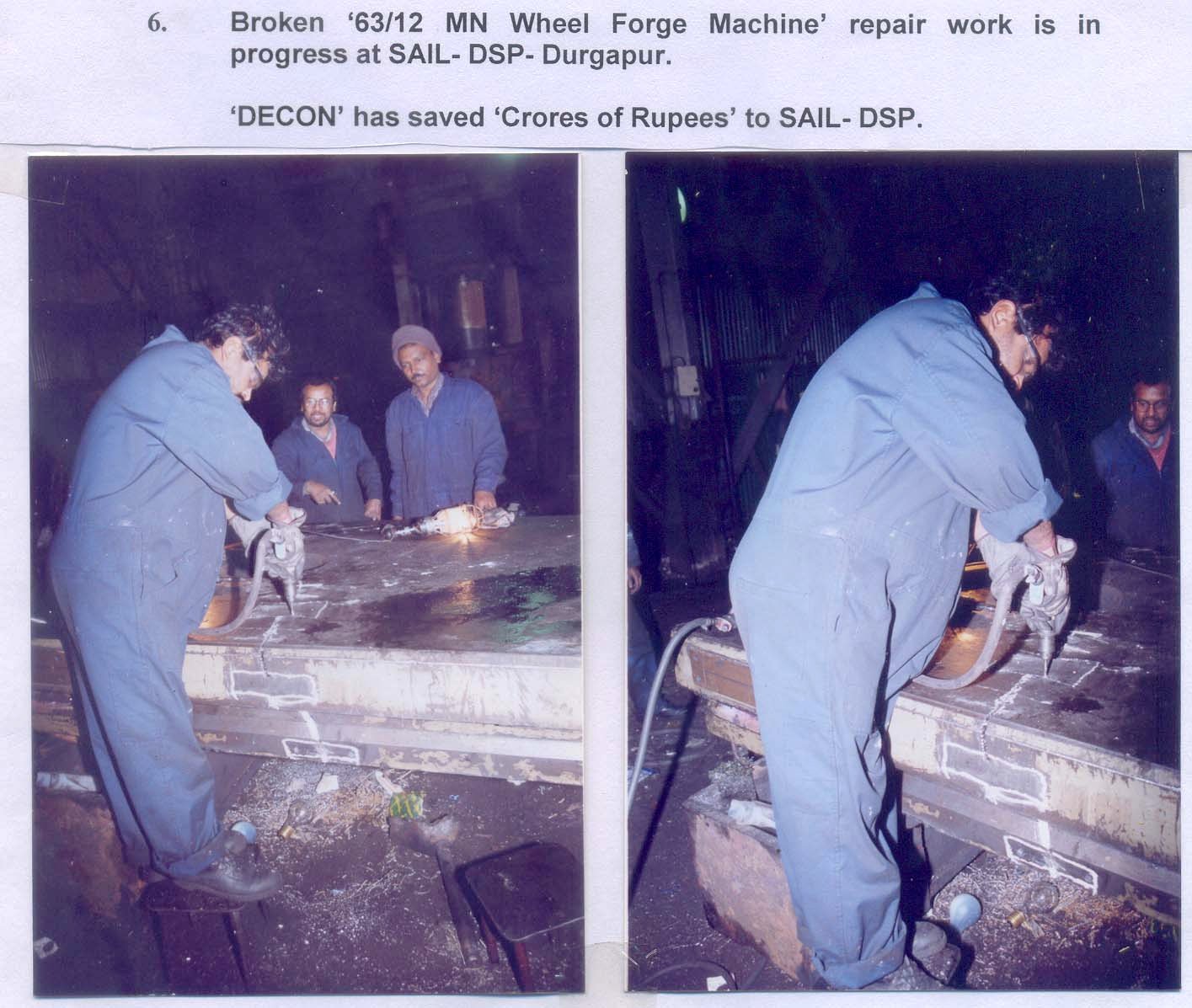

BOTTOM TABLE OF 63/12 MN WHEEL

FORGE MACHINE UNDERGONE REPAIR

AFTER BROKEN

|